My 99 e300d has the om606 engine. It’s a fantastic motor, but it has one serious issue to look out for: seized glow plugs. They’ve got a really bad habit of seizing up near the tip, and breaking off when you go to change them. It’s not an issue with the threads seizing, it’s the actual body of the plug seizing into the head. Really scary stuff.

Some people go as far as pulling the plugs every year, reaming out the carbon deposits, and putting them back in. Unfortunately, you have to take off the intake manifold to get at them. Seem like overkill? It’s better than pulling the engine head when one seizes.

When I bought my car, one of the major “pluses” was the fact that the plugs had been changed 2 years ago. That meant they were far less likely to be seized.

As part of the vegetable oil conversion, the intake manifold needs to come off to facilitate re-routing the fuel lines around the lift pump, injection pump and shut-off valve. While the manifold was off, I thought it would be wise to pull the glow plugs and ream out the carbon deposits, using a reamer bought on the mercedesshop forum.

So I prepared myself by reading this step by step guide, and sufficiently spooked, I set to work.

Numbers 1, 2 & 3 came out slick & easy. Number 4 was a bit stiff, but not nearly as much as #5 & #6. They all moved though, and I worked them slowly back & forth using penetrating oil. Leaning on the side of caution, I never went over 35 ft/lbs. I figured if I could keep them wiggling at that torque, I'd be all set. I took turns on the 3 stubborn (but not stuck) glow plugs, giving each one a couple back & forths, then to the next one. I was working on other things, so I'd just do it every 5-10 minutes so the metal wouldn't get hot.

Of those 3 plugs, #4 was the one that was moving best. Then, it just busted off at 30 ftlbs. And it busted off at the head, leaving the shoulders still threaded in. Ba$tard.

I was pretty much in shock when it broke off… I wasn't even at 35 ft lbs. The only theory I have is that the threads were messed up and they may have ham-fisted it in there last time, weakening the "neck" of the GP. The "nub" around the hole was a little beat up, and the threads are not quite "right" at the top. Looks like someone had crossthreaded one and then gone back to fix the threads. I don't know how you could crossthread one though.

Anyway, it was back to the mercedesshop forum. I found these two threads describing how to make a puller:

http://alan.mcreynolds.googlepages.com/howtoremovebrokenglowplugs-mercedesom606

http://www.mercedesshop.com/shopforum/showthread.php?t=109101&highlight=606+%22glow+plugs%22

You want that part gone, allowing you to pull the seized “body” of the plug straight out. I started with a small bit, and then worked my way up, until there was just a little thin ring of steel left… if you go crooked, you’ll mess up the aluminum head. If you get it straight, you can just pick out the threads with a pic or sharpened screwdriver.

Anyway, I've drilled out the threaded portion of the GP, and unwound the steel threads from the aluminum head. Threads still look OK.

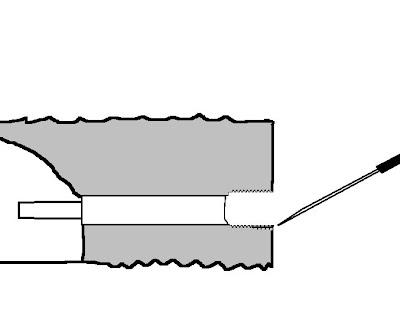

So that left me with just the body of the plug in there. Now I needed to drill & tap the glow plug body, and pull it out. The goal now was to drill a hole about 1-1.5 CMs deep, and then thread it with a tap.

I set a GP in the hole next to it, so I could eyeball the angle. Then I started with a small bit and drilled a hole in the electrode that goes down the middle. Doing that, I could pretty much see if I was wandering. I started with a 11/64 bit, and worked my way up to 9/32.

Then I threaded the hole in the glow plug with a 5/16 tap:

I took a 6” long piece of threaded rod, and screwed it into the glow plug.

Then, I slid a ½” socket over the rod; it seats against the engine head. I then put a couple washers on top of the socket, and then a nut.

Tightening the nut against the socket pulls that rod, and the glow plug:

I could feel the resistance, and you can really tell when it breaks free. I took my time, and had it out within a few minutes.

This was easily one of my happiest moments as a DIY mechanic:

One thing I can guarantee: That intake manifold is coming off every fall, and the glow plugs will be pulled so I can ream those holes. Never going through this BS again. I lost a LOT of hair this weekend.

3 comments:

Just wanted to leave you a note and say this is an EXCELLENT blog. I have two VO vehicles already and I just bought a mint 1999 E300 destined for conversion this spring. Thank you very much for sharing your experiences with us. BTW: I just paid $350 for a trusted mechanic to change the glow plugs on the E300. I feared having your experience. Nice job documenting how to fix it when it occurs.

thanks chris

if you are planning on converting yours, have a look at my plumbing diagrams and tell me if they make sense to you!

I'll be posting my wiring diagrams soon.

FWIW, at first I didn't think teh VegMax would fit under the hood, but it fits beautifully, and can be lifted out for filter changes.

Excelent work and blog. I just had the same job done at a cost of 2400.00 i was first quoted 4500.00. The mechanis said change and reem every 50K miles and probably more frequent and veggi.

Post a Comment